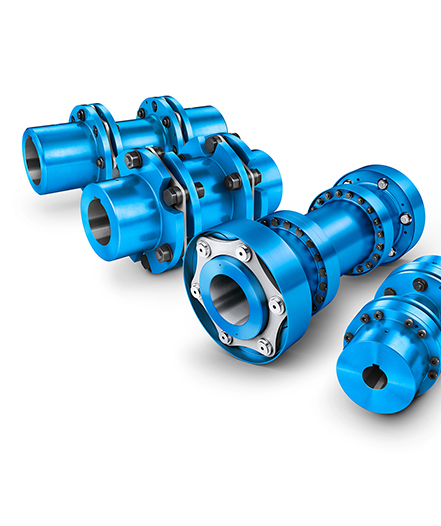

ARPEX All-Steel Coupling

- Torsionally rigid, backlash-free, all-steel multiple-disk coupling

- Nominal torque range from TKN = 5 Nm up to 10,000,000 Nm

- Temperature range: from –40 °C to +280 °C

Versatile and compact

ARPEX® all-steel couplings are very compact and stand out due to their particularly good power-to-weight ratio. Their versatility makes them suitable for universal use.

In these all-steel couplings, the torque is transmitted by torsionally rigid, flexible disks. The disks are joined together with bushes and rings to form a compact disk pack which ensures easy and reliable installation.

Two disk packs connected to a spacer are capable of compensating for axial, radial and angular shaft misalignments. Couplings with one disk pack can only compensate for angular and axial misalignments.

The ARPEX coupling covers a wide range of products by means of many different series and sizes:

- ARS-6 series: standard series for universal use

- ARC-8 series: optimized for high torques

- ARP-6 series: optimized for pump drives (according to API 610/API 671)

- ARW-4/6 series: optimized for large shaft misalignments

- ARF-6 series: optimized for extremely restricted space

- Composite series: optimized for drives with large shaft distances

Your benefits at a glance

- Compensation in angular, radial and axial shaft misalignment possible

- Independent of the direction of rotation (suitable for reversing operation)

- Torsionally rigid and free of circumferential backlash

- Low restoring forces

- Low-vibration (even with maximum permissible speeds)

- Easy assembly through compact structural design

- Conformity to API 610 and API 671

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

Made in Germany, worldwide in use

- Mining and Cement: conveyor belts, apron conveyors, bucket elevators, tube mills, bucket excavators, crushers, roller presses, separators, heating technology, slurry pumps

- Steel Production: shears, reversing rolling mills, pilger rolling mills

- Cranes: hoisting and luffing gear system, slewing gear systems, trolley and travel gear systems

- Marine and Shipbuilding: single-engine ships, multi-engine ships, dredgers, generator gearboxes, installation vessels

- Oil and Gas: installation vessels, pumps, fans, compressors, air condensers, jack-up rigs

- Power Generation: air condensers, generators, gas turbines, cooling towers, water turbines, boiler feed pumps

- Chemicals and Pharmaceuticals: driers, pumps and compressors, mixers, cooling towers, agitators, reactors

- Plastics and Rubber: single- and double-screw extruders

- Pulp and Paper: waste paper, wet section, dry section, smoothers and cylinders, reel winders, coating machines, calenders, wastewater purification plants

- Water and Wastewater: aerators, water screw pumps

- Food and Beverage: lauter tuns, reactors, agitators, mixer drives, filling systems

- Sugar: generators, steam turbines, sugar cane mills

- Railway Vehicles: railway couplings

- Passenger Transport: cable cars

- Other fields of application: test benches, wood milling, packaging machines

Did you know?

All coupling parts like hubs, spacers and flanges are manufactured from high-grade steel; the plates are made from stainless, hard-rolled CrNi spring steel. This is why the ARPEX does not need maintenance and operates without wear. Thus, a very long service life can be ensured. Our ARPEX couplings deliver the proof: they have been in use in the most diverse applications for decades.

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services