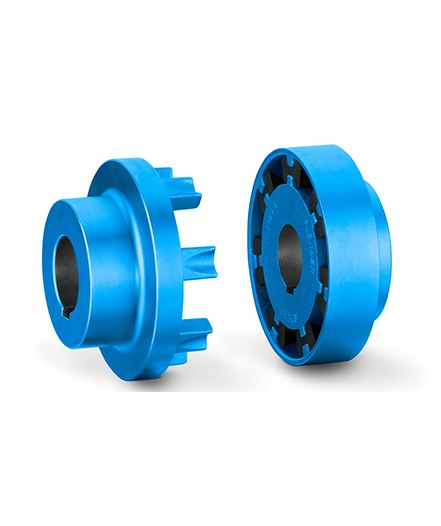

N-EUPEX Pin Coupling

- Damping shaft coupling that can be used universally to compensate for shaft misalignment

- Nominal torque range from TKN = 19 Nm up to 62,000 Nm with 23 sizes

- Temperature range: from –50 °C to +100 °C

Robust and proven a million times

Due to their torsional flexibility, N-EUPEX® couplings can move critical torsional vibrations away from the operating area of mechanical equipment in such a way that no negative effects on the drive train are to be expected. N-EUPEX couplings are made of high-quality cast iron. The flexible elements made of synthetic rubber (Buna-N) are available in different degrees of hardness for many applications. Metal pins and flexible elements are designed so that no wear occurs when they are properly fitted.

Your benefits at a glance

- Fail-safe for maximum operational reliability

- Three-part type suitable for plug-in assembly and simplified replacement of elements

- Choice of elastomer hardness to suit various applications

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

- High degree of availability of parts ex stock

Established as an industrial standard, worldwide in use

- Mining and Cement: heating technology

- Oil and Gas: pumps, fans, compressors, air condensers

- Power Generation: pumps, fans, compressors, air condensers, water turbines

- Chemicals and Pharmaceuticals: driers, lauter tuns, pumps, fans, compressors, mixers, agitators, reactors

- Plastic and Rubber: single- and double-screw extruders

- Pulp and Paper: wastewater purification plants

- Water and Wastewater: aerators

- Food and Beverage: lauter tuns, reactors, agitators, mixers

Did you know?

Original FLENDER® elastomers ensure the optimal operation of your system. The flexible elements of the N-EUPEX coupling are subject to compression. If the flexible elements are irreparably damaged, the hub parts come into contact with metal. This “emergency operation capability” is required, e.g., in the case of fire pump drives.

Catalogs

Technical information

Operating Instructions 3100 N-EUPEX / N-EUPEX DS – A, B, ADS, BDS

Operating Instructions 3101 N-EUPEX / N-EUPEX DS – H, HDS

Operating Instructions 3102 N-EUPEX – D, E, M

Operating Instructions 3103 N-EUPEX – O, P

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services