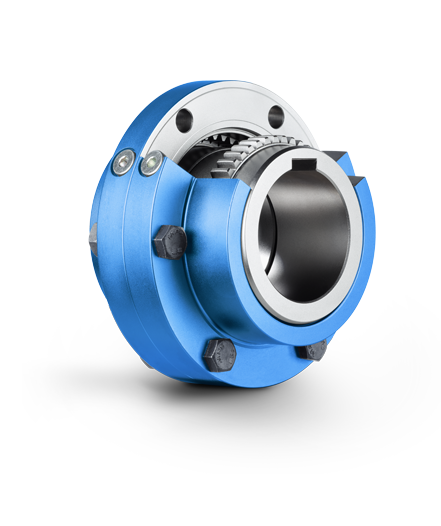

ZAPEX ZN Gear Coupling

- Double-jointed gear coupling

- Nominal torque range from TKN = 1,020 Nm up to 162,500 Nm with 12 sizes

- Temperature range: from –20 °C to +80 °C

Strong and reliable

ZAPEX ZN® couplings connect machine shafts and compensate for angular and radial misalignment. ZAPEX gear couplings from the ZN series are made of high-quality quenched and tempered steel and are manufactured according to the modular construction system.

Your benefits at a glance

- Long service life and minimal maintenance requirements as a result of reliable grease lubrication of the gear teeth

- Small dimensions, low weight and low mass moments of inertia are achieved by means of an intelligent design and combination of materials

- Large safety reserves even at high shock loads

- Maximum operational reliability through optimal tooth shape and use of high-quality materials

- Suitable for horizontal mounting and, with a special design, for vertical mounting

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

Made in Germany, worldwide in use

- Mining and Cement: conveyor belts, heating technology

- Steel Production: milling technology, shears, straightening machines, high mills, coilers, roller conveyors

- Cranes: hoisting and luffing gear systems, slewing gear systems, trolley and travel gear systems

- Marine and Shipbuilding: thrusters

- Oil and Gas: installation vessels, pumps, fans, compressors, jack-up rigs

- Power Generation: water turbines

- Chemicals and Pharmaceuticals: driers, pumps and compressors, mixers, agitators

- Plastics and Rubber: kneaders, shredders

- Pulp and Paper: woodgrinders, waste paper, wet section, dry section, smoothers and cylinders, calenders

- Water and Wastewater: pumps

- Food and Beverage : mixers

- Sugar: countercurrent cossette mixers, sugar cane mills

- Passenger transport: cable cars

Did you know?

The design of the ZAPEX ZN coupling’s hub has been optimized with regard to the maximum capacity of the bore range (up to 288 mm). Due to the smaller and more compact size of the coupling, bearings within the driving and driven machine are less loaded. A long service life of the drive can be ensured.

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services