Agitators

Keeps stirring…

Agitators and agitator tanks are used in chemical, pharmaceutical, cosmetic, and food processing applications. The diversity of the application requirements and the media employed necessitate customized plant designs.

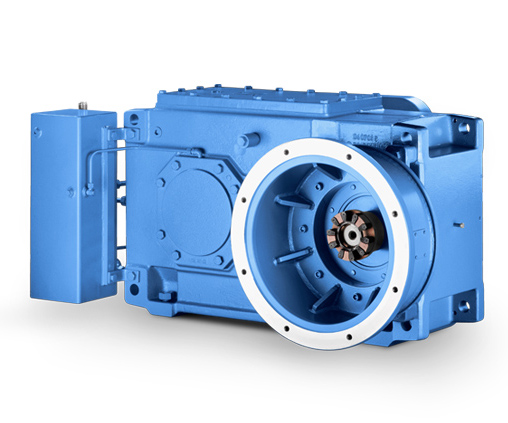

The gear unit is normally vertically mounted to the agitator tank. In addition to transmitting torque, it also absorbs the axial and radial loads that occur as a result of the application’s specification. FLENDER gear units for agitator drives have a reinforced output shaft and rolling-contact bearings for this purpose.

Even in special cases with very high axial loads, FLENDER can supply gear unit solutions with an additional thrust bearings.

Your benefits at a glance

- High operational reliability

- Reinforced bearings

- Optional, force-free gear housing thanks to additional thrust bearing

- Customized versions possible, special flange on the output side for mounting to the agitator

- Extra-strong output shafts (solid- or hollow-shaft design)

- Output bearing arrangement with additional, bidirectional thrust bearings

Application

- Chemical, pharmaceutical, cosmetic, and food processing industries

Technical Data

| Rated Torque | Up to 240,000 Nm |

| Transmission | i = 1 … 450 |

| Power | Up to 4,000 kW |

| Translation Stages | 1- to 4-stage |

| Sizes | 18 |

| Mounting Position | vertical |

| Type | Helical and bevel-helical gear units |

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services