Trolley travelling winch and travelling gear

High operational reliability for trolley travelling-gear and travelling-gear drives

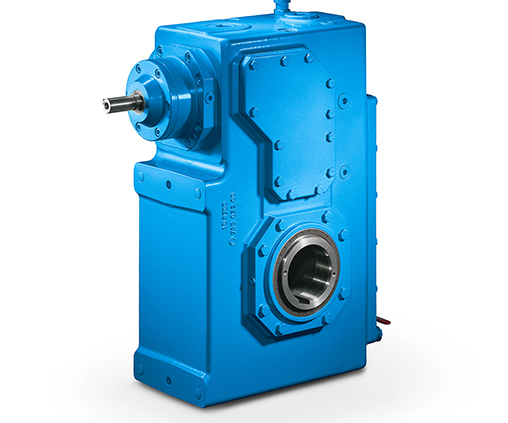

Whether it is trolley travelling-gear, or rail-borne or tyre-borne travelling-gear, every application makes quite specific demands of gear-unit design that have to be taken into consideration. The FLENDER gear-unit series optimised for these areas of application stands out for highest possible reliability, highest possible quality and long service life, whatever the loads placed on the gear units, for example, on container cranes. Output torques from 10,000 up to 75,000 Nm can be realised.

Your benefits at a glance

- Extensive accessory range: motor bell housings, motor consoles and torque arms, etc.

- Variable arrangement of drive shafts possible

- Diverse mounting positions

- Optimised sealing systems with long shaft-sealing ring service lives

- Very long service life and long oil lives

- Low weight

- Low noise thanks to ground gear teeth and sound-damping housing

In many cases standard gear units from the universal gear-unit range can be fallen back on.

Your benefits at a glance

- High flexibility for project-related special solutions

- Short delivery times

- Excellent price-performance ratio

- Proven FLENDER Quality

Applications

- Container cranes

- Bridge cranes

- Casting cranes

- Tower slewing crane

- Offshore cranes

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services