Drying cylinders

As various as the requirements – FLENDER Gear Units for Drying Cylinders

The dryer section is the most power consuming part of a paper or paperboard machine (up to 65% of the energy costs of a paper machine occur in the dryer section). In the dryer section, the remainder of the paper web moisture is evaporated. The water content of the paper web after passing through the press section is about 50% to 65%. Depending on the size and speed of the paper or paperboard machine, up to 100 drying cylinders may be available in the dryer section.

In the drives in the dryer section, a differentiation is made between felt guide roll drives and direct-drive drying cylinders.

In felt guide roll drives (silent drives), standard drive components such as FLENDER helical or bevel helical gear units are used.

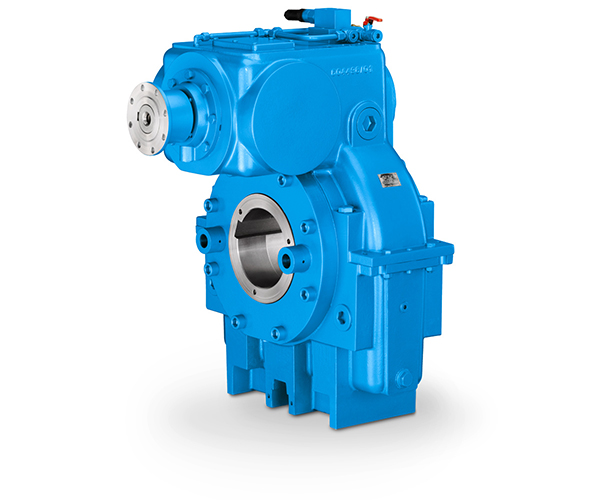

In direct-drive drying cylinders, a distinction is made between shaft-mounted and foot-mounted drying cylinder gear units (cylindrical bearings integrated in the gear housing). In most cases, shaft-mounted gear units are used. These gear units are mounted on to the cylinder pin. The steam required for drying is fed through the hollow-bored cylinder pin into the cylinder at a temperature of around 120 °C to 180 °C.

Since the 1950s, paper machines have been equipped with FLENDER shaft-mounted gear units for drying cylinders. The gear units are available in various designs so that the most varied drive problems in this area can be solved. FLENDER shaft-mounted gear units for drying cylinders are available as single gear units and group drives. Group drives with two to eight interconnected gear units are available for both slalom drives as well as for top and bottom wire guides. The hollow shaft inside diameter can be up to 220 mm.

Your benefits at a glance

- Maintenance-free labyrinth seals

- Emergency running properties in the event of oil supply system failure

- Hollow shaft inside diameter up to 220 mm

- Gear unit can handle axial forces from the steam head of up to 12,500 N.

Applications

- Dryer section

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services