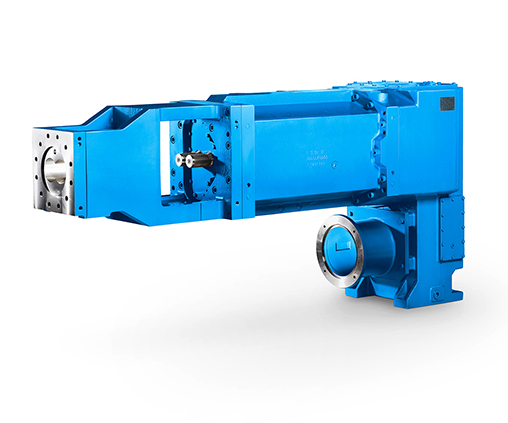

Double screw extruder

Maximum performance level, fast deliverable

FLENDER helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are available in several sizes in the performance range between 200 and 35 000 Nm per shaft and for up to 20 000 kW. They are used mainly in the manufacture of granulates and the refining of raw plastics as well as in the paint and lacquer industry and in the washing agent, foodstuff and animal-feed industries.

FLENDER extruder gear units are the best drive in all cases, because they are high-performing and reliable. Because of their long service life and their need for little maintenance work, they represent an economically attractive solution worldwide.

FLENDER has the greatest experience with gear units in the world market and provides customers with extremely high-performing products, as well as tried and tested engineering expertise and a full service. FLENDER helical gear units for double-screw extruders are also extremely standardised and allow customer-specific configurations without any problem. For instance center-distance modifications can be realised with very little construction effort and expense, so enabling cost-optimised customer-specific variants.

Double-screw extruder (synchronous)

To be able to absorb the very high torques and axial forces set up by the extrusion process, we have developed an extruder gear unit with a double power-splitting system and special thrust bearings. The bearing system can consist of up to eight thrust bearings layered one behind the other. Output torques of from 200 to 35,000 Nm and center distances between 18.3 and 140 mm can be realised. Furthermore we can offer customer-made solutions of up to 20,000 kW.

Your benefits at a glance

- Gear unit with maximum power performance

- Short delivery times thanks to consistent standardisation of the housings and interior parts

- Center-distance modifications can be realised fast and with minimum engineering effort and expense.

Applications

FLENDER helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food)

Double-screw extruder (contra-rotatory)

In the field of extrusion, as well as co-rotatory double-screw extruder gear units, FLENDER also offers contra-rotatory double-screw extruder gear units in vertical and horizontal versions. Thanks to consistent standardisation of the housings and interior component parts we can ensure short delivery times. Customer requirements can be quickly realised with minimum engineering effort and expense, regardless of the direction of screw rotation. Center distances between 60 and 140 mm and output torques between 5,000 and 60,000 Nm can be realised.

Your benefits at a glance

- Absorption of very high torques and axial forces

- Short delivery times for gear units with preferred center distances

Applications

Most versatile areas of application such as:

- Pipes (waste-water pipework, floor pipework, ventilation pipework)

- Profiles

- Window frames

- Sidings

- Foils

- Packing material

- Heat-insulating boards

- Rotor blades for wind turbines

- Tyres

- Assembly lines

- Conveyor belts

- Fittings for automotive industry

Technical Data

| Rated Torque | (A) up to 10,200 Nm; (B) up to 60,000 Nm |

| Transmission | (A) i = 1.0 to 5.6; (B) up to i = 112 |

| Power | (A) up to 2,000 kW; (B) up to 450 kW |

| Translation Stages | (A) 1-stage; (B) 3-stages |

| Geartype | (A) 11; (B) 4 |

| Type | (A) TF1L, TF1R; (B) TG3U, TG3H |

| Direction | A = co-rotating; B = counter-rotating |

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services