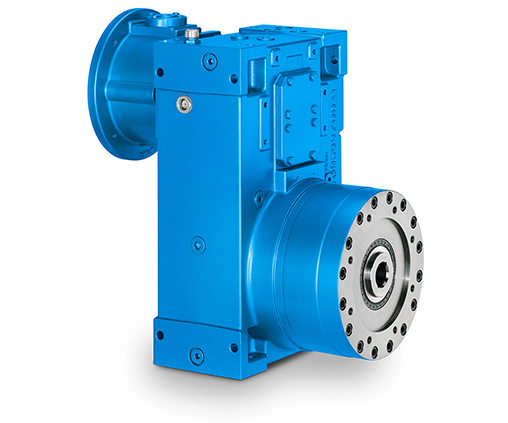

Single screw extruders

Single Screw – Many Output

In the manufacture of rubber and plastics, the great variety of materials requires very high precision of the processing machines. Only then can the high expectations of customers regarding the final product be met. The high axial forces from the extrusion process must be absorbed. Our single screw extruder gear units are mainly used in plants for plastic forming, and are characterized by high operational reliability and short delivery times. The standard series comprises 2- and 3-stage helical or worm gear units with either integrated thrust bearings or thrust bearings fitted in front of the gear unit. Output torques from 6,300 to 173,000 Nm are possible.

Your benefits at a glance

- Compact design

- Low noise emission

- Highest axial forces possible due to thrust bearings fitted in front of the gear unit

- Highest operational reliability due to thrust bearing in gear unit oil chamber

- Reduced delivery times

Applications

Wide range of applications, e.g. for:

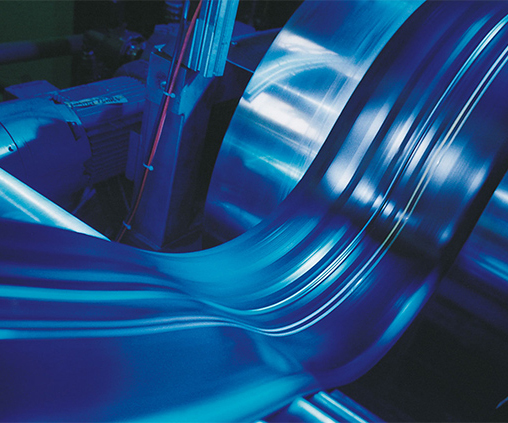

- Rubber for conveyor belts

- Automobile tires

- Plastic film/sheets, e.g. packaging film, carrier bags, tarpaulins for fields

- Cling film, food storage bags

- Packaging (Tetra-Pak)

- Thermal insulation boards (polystyrene)

- Rotor blades for wind turbines

Technical Data

| Rated Torque | Up to 173,000 Nm |

| Transmission | i = 6,3 … 28 |

| Power | Up to 4,500 kW |

| Translation Stages | 2- and 3-stage |

| Geartype | 11 |

| Type | E2HA, E3HA |

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services