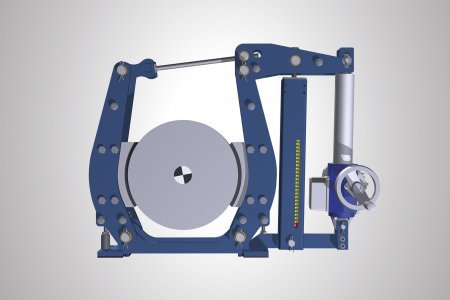

Parking / Holding brake

Parking brakes, also know as holding drum brakes are constructed for fixing and securing of industrial machines in case of maintenance and in case of unwanted movements.

This type of drum brake is a static holding brake and not usable for dynamic braking solutions. An additional advantage of this solution is that all shaft diameter in between the DIN standards from 140 mm up to 750 mm can be achieved and fixed.

Application areas:

- Crane systems

- Steel industry

- Mining / Material handling

- Wind industry

- Railbound hall roofs / gates

- Offshore / Ship

Product type:

- Block / Parking brake

Product description

Particulary suitable as static holding drum brake ( not suitable for dynamic brake applications). Movements during maintenance work or unintended machine movement on e.g. ship shafts, large fan systems, wind turbines or industrial installations will be avoided.

- Adjustable to any shaft diameter (140 up to 750 mm)

- Brake shoes according to customer requirements

- Brake torques up to 10563 Nm per brake system

- 9 brake sizes

- Twin-bar brake lever version

- Base frame drum brake type TB according to DIN

- Standard painting RAL 5009

- NOT self-acting in case of power failure

- MADE IN GERMANY, own production

Functional principle

Brake blocks are fixed mounted between the brake levers using screw connection instead of having hinged mounted brake shoes acc. to DIN 15435.

The contour of brake blocks are manufactured by circular milling relating to the relevant body of rotation (e.g. a shaft, a brake drum, etc.). Therefore any diameter is realizable as body of rotation within a brake drum size acc. to DIN 15435.

{{ Betätigungsarten }}

- Operated by actuator

or - Operated via hand wheel

Options

- Mechanical lLimit switch position control

– “Brake open”

– “Brake close”

– “Brake Check / Wear” - Special brake lining acc. to customer requirements

- ATEX version

- Special construction

- Special painting (Please specify RAL color)

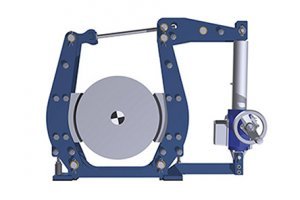

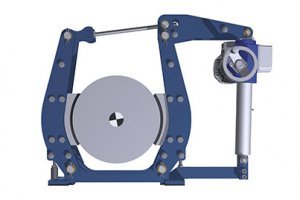

Gallery

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services