Parameters for screw pumps

The actual performance of a Screw Pump depends on several parameters which are all related to each other. The selection of the right combination of these parameters therefore is an essential but specialized task since it will be decisive for the performance and life-time of the pump.

But do not fear! Spaans Babcock will make the right selection for you. You just tell us the required capacity and lift.

The Gap

The screw, suspended between the upper and lower bearing, is rotating above the trough with a minimal gap of only a few millimetres between the flights and the trough. Some water will flow back through this gap, however this is marginal as long as the gap remains within allowable limits. The smaller the gap, the better the pump efficiency. On the other hand the gap must allow for some deflection of the pump body! In order to maintain an even and accurate gap along the total length of the screw it is important that the deflection of the screw pump is kept to a minimum.

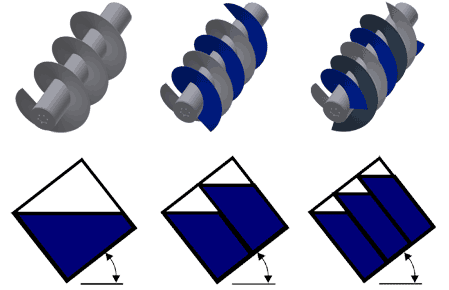

D/d = Outside diameter and Centre tube diameter

The outside diameter of the screw pump in combination with the diameter of the centre tube are essential factors for the capacity of the pump. For long screw pumps a larger centre tube will be required (figure c) to control the deflection, but this will have an effect on the effective capacity.

Number of Flights

The effective filling between the screw blades increases with the number of flights. However the price of the pump will also be influenced by the number of flights. For some situations a 1-flight screwpump will be sufficient.,For each situation Spaans Babcock will search the optimum solution!

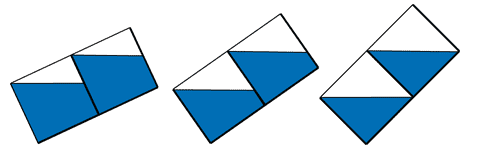

Installation Angle

As you can see from the simplified sketch below: the lower the angle of inclination with the horizontal axis, the better the effective filling >ergo> the better the pump efficiency. However, when the required lift is rather high, we need to increase the angle in order to keep deflection of the screw within allowable tolerances.,Spaans Babcock has standardized angles at 30º, 35º and 38º. Other angles are possible on request or recommendation from Spaans Babcock but will always be between 22º and 40º.

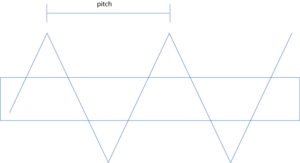

Pitch

The pitch is another parameter which will affect the capacity of the pump; Spaans Babcock does not follow a fixed rule (e.g.: pitch=D) however elects different pitches for various angles.

Rotation Speed

Each specific pump has its own optimum speed. Spaans Babcock uses the formula of ir. Muyskens to determine the optimum speed.

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services